Profab's current fabrication capacity for process modules, skids and PAUs is approximately 25,000 tonnes per year and is regularly increasing. Our workforce gives us a capacity of 4 million manhours/annum with the flexibility to man up, based on project requirements.

We also have our own Caterpillar generators with up to 1.8 Megawatts of utilities, to ensure production can continue in the event of main power failure.

Layout Capacity

Profab's workshops are purpose built to provide the most efficient fabrication and assembly processes. Increased productivity through the design of production systems, that minimizes handling throughout the various workstations enable us to produce equipment at a faster and more competitive rate.

Our

140,000m² yard houses 27,500m² of workshops (7 workshops) holding an impressive inventory of handling

and fabrication equipment including multiple overhead cranes from 5 - 20 ton,

jib cranes, a 70 ton Pedestal.

New Blast and painting section boasts an automated blast line and segregated paint bays to enable multiple jobs to be coated concurrently. Airless spray units, conventional spray guns and an air conditioned paint store.

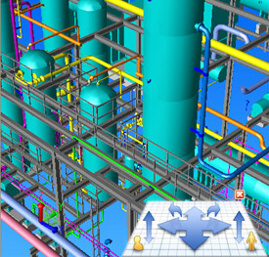

Design Engineering

Profab has an experienced team of design engineers and CAD draftsmen using design packages including PV Elite, Tekla, NozzlePro, Cadwork (3D) and AutoCAD for its detail design and drafting, Also we can design and fabricate to all design standards, including but not limited to

■ ASME VIII Div, 1, 2, 3 (U, U2, R and S Stamp)

■ PD 5500

■ AS 1210

■ ANSI B31, 3/B31.8

■ API 661 / API 1104

■ AWS D1.1

Equipments

Profab's pre-fab workshop equiped with CNC Universal Beam Coping Machine, Multi Head Flame Cutting Machine, Hydraulic Beam Straightening Machine, Beam Gentry Welding Machine, Beam Assembly Machine, Profile Bending Machine, CNC Vessel and Pipe Profiler, Tin and Thick Plate Rolling Machine.

The machine shop houses a large collection of lathes, band and drop saws, vertical bores hydraulic punches.

Profab's coating experience includes Epoxy,

polyurethanes, plastite, thermally sprayed aluminium glass flake, nova coats,

coal tar epoxy and more.

Overlay cladding equipment includes Euroweld Strip machines, and Hot Wire GTAW Cladding Rigs.